Pingxiang Volmet Import&Export Trading Co., Ltd. 萍乡市沃美特进出口贸易有限公司

Current Transformer APG Mold 1 Cavity

Short Description:

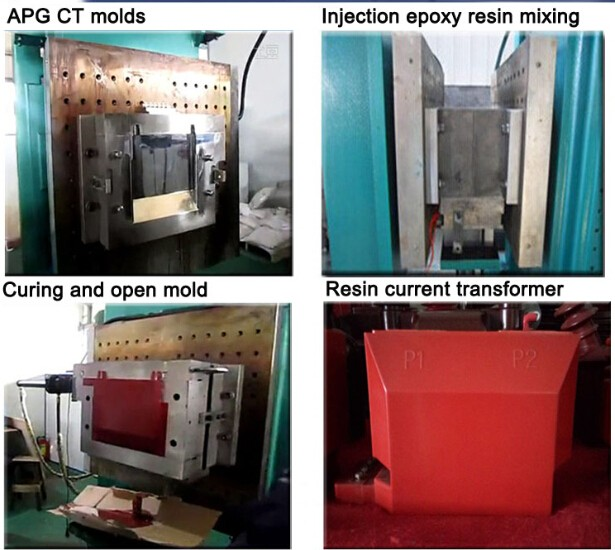

APG CT mold used for casting epoxy resin CT,supply trail mold and make sample service

Contact Us

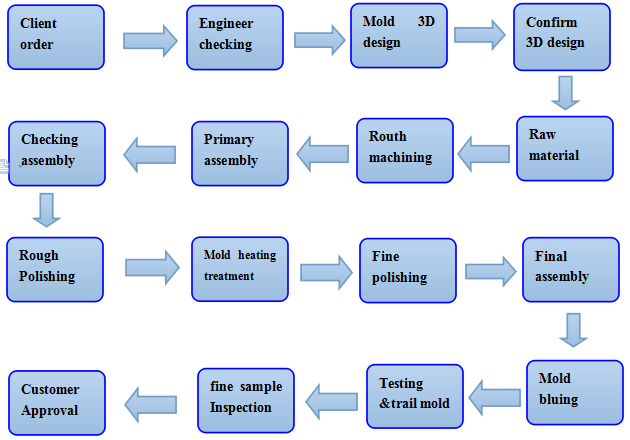

APG Mold Production Flow Chat:

Application:

instrunment transformer apg mold used for produce current transformer from 11-36Kv:

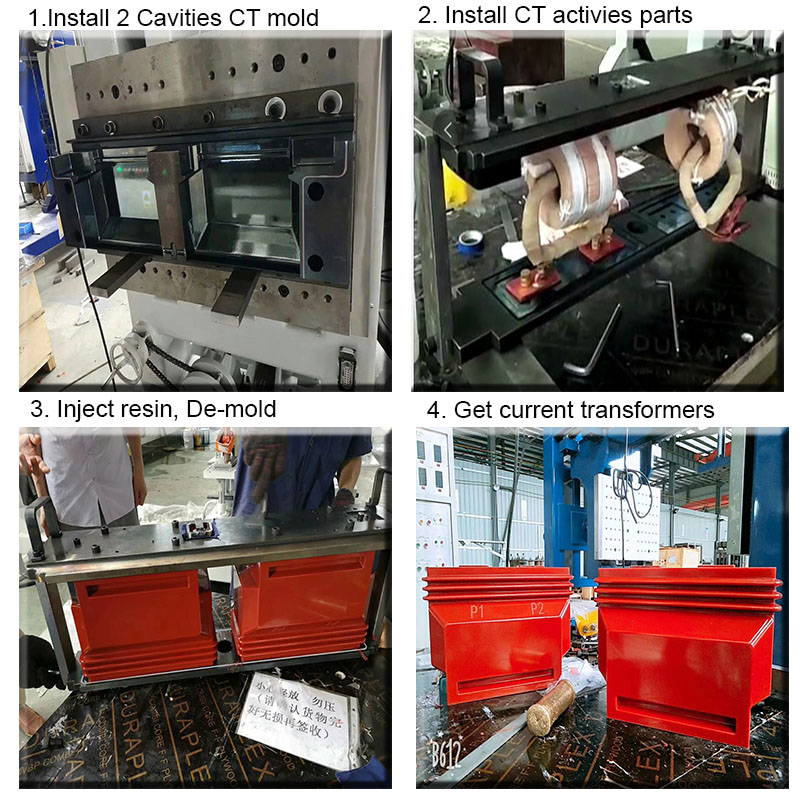

Epoxy Resin Current Transformer Casting Process By APG Molding Machine:

1.Step 1: install Current transformer APG Mold on APG clamping machine

2.Step 2: install accessories,inserts into APG mold.

3.Step 3:Clamping apg machine,injection epoxy resin into mold.

4.Step 4:Epoxy resin curing inside mold,open clamping plate,take out product.

2 cavities current transformer apg mpld

Mold Material:P20

Hardened

In order to improve the life of the mold to more than 800,000 mold times, the pre-hardened steel can be quenched and low temperature return

The hard way of fire to achieve. When quenching, preheat at 500-600°C for 2-4 hours, then keep it at 850-880°C for a certain period of time (at least 2 hours), then put it in oil and cool to 50-100°C and air cooling. After quenching, the hardness can reach 50. -52HRC, in order to prevent cracking, 200℃ low temperature tempering treatment should be carried out immediately, after tempering, the hardness can be maintained above 48HRC

Nitriding treatment

Nitriding treatment can obtain high hardness surface structure, the surface hardness after nitriding reaches 650-700HV

(57-60HRC) The service life of the mold can reach more than 1 million times. The nitride layer has the characteristics of dense and smooth structure, and the mold release performance and resistance to humid air and alkali corrosion are improved.

Delivery status: The steel is delivered in annealed and hot rolled state.

Material characteristics

● Uniform hardness, good polishing performance and photo-etching performance, good processing performance.

● Vacuum degassing and refining process pure steel, suitable for plastic molds that require polishing or etching.

● Supplied in a pre-hardened state, it can be directly used for mold processing without heat treatment, shortening the construction period.

● After forging and rolling, the structure is dense, 100% ultrasonic inspection, no pores, pinhole defects.

Shipping Mold:

Clients:Trail Mold,Make Voltage Transformer Samples Before Delivery After Inspection